The list of mandatory Personal Protective Equipment (PPE) is derived from the risks you face. Here are the 3 steps to identify the mandatory individual (PPE) or collective (CPE) protective equipment for your activity:

- Identify and assess risks

- Eliminate or reduce risks

- Choose the protective equipment to implement

If you fail to perform one of these steps, you put your employees at risk and expose your company to legal liability. Here is the complete process.

Step 1: Risk Assessment

A risk is an event whose occurrence endangers people in the exercise of their profession. Identifying a risk involves studying the exposure conditions of personnel to hazards and defining the severity of its effects.

The first step is to identify and analyze the specific hazards at your workplace. This assessment must cover all potential risks, whether they are mechanical, chemical, biological, or other. The objective is to understand which specific threats your employees may face and to evaluate the likelihood and potential impact of these hazards on their health and safety.

Hazard Identification

Hazard identification is the first step of risk assessment. This involves examining working conditions to identify situations, substances, or practices that have the potential to cause harm. Common methods include:

- On-site inspections: Examine workplaces to identify both visible and less obvious hazards.

- Consultations with employees: Engage employees to obtain information about the hazards they perceive in their work environment.

- Document analysis: Review incident reports, data on past accidents, and occupational diseases to identify trends and potential hazards.

Example: In a manufacturing plant, an on-site inspection reveals that several machines lack adequate protections to prevent crushing or cutting injuries. Additionally, employees frequently report exposure to potentially harmful chemical vapors when using certain solvents.

Risk Assessment

After identifying hazards, the next step is to assess the associated risks. This involves determining the likelihood that a hazard will cause harm and the severity of that harm. Factors to consider include:

- The frequency of exposure to the hazard.

- The severity of potential consequences if the hazard occurs.

- The ability to control the hazard.

Example: After identifying hazards related to the lack of machine protections and exposure to chemical vapors, the assessment reveals that employees working on or near unprotected machines are at high risk of serious injuries, such as deep cuts or fractures. Exposure to chemical vapors is deemed moderately risky, with potential health effects such as respiratory issues or skin irritation.

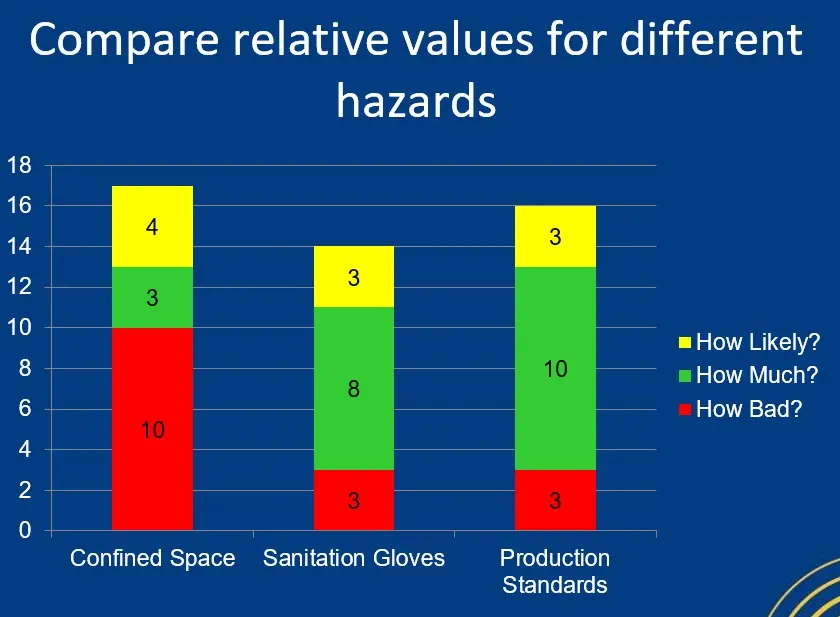

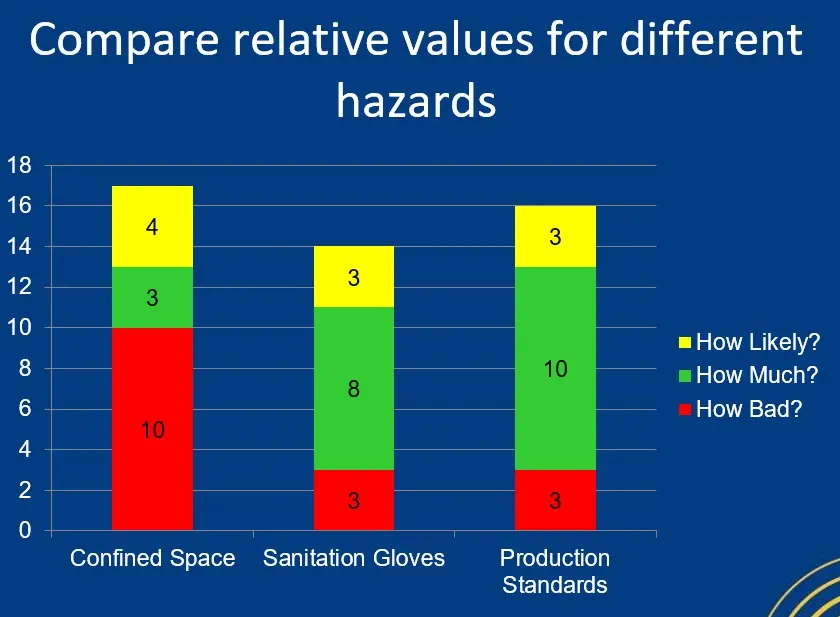

Risk Classification

Risks are generally classified according to their severity using a risk matrix, which crosses the likelihood of occurrence with the severity of consequences. This classification helps prioritize risks for mitigation, with the highest risks addressed first.

Here is an example from the OSHA (Occupational Safety and Health Administration):

.

.

Example: Using a risk matrix, the company classifies the risk of injury from machines as “high” due to the high probability of occurrence and the severity of the consequences. Exposure to chemical vapors is classified as a “moderate” risk, given a lower probability of severe short-term effects but a potential long-term impact on health.

Step 2: Risk Reduction

Before turning to PPE, it is necessary to examine whether risks can be eliminated or reduced by other means. This includes eliminating the hazard, substituting with less dangerous alternatives, engineering controls to isolate people from risks, and administrative controls to change the way people work. PPE should be considered as a last resort.

Example: To mitigate the risk related to machines, the company installs safety guards and emergency stop devices on all concerned machines. To reduce exposure to chemical vapors, it replaces hazardous solvents with less harmful alternatives and installs improved ventilation in affected work areas. Additionally, gloves and masks are made available to employees, and training on safety procedures and the correct use of personal protective equipment (PPE) is provided.

Step 3: PPE Selection

Once you have determined that the use of PPE is necessary, select equipment specifically designed to protect against the identified risks. It is essential to choose PPE that meets the required safety standards and is suitable for the specific task. Comfort and fit are also important to ensure that the PPE will provide effective protection.

Before you buy checklist:

- Compliance with standards: Ensure the PPE meets the applicable safety standards. In the US, PPE should comply with standards set by organizations such as the Occupational Safety and Health Administration (OSHA), the National Institute for Occupational Safety and Health (NIOSH), and the American National Standards Institute (ANSI). For example, respirators should be NIOSH-certified.

- Certification: Verify that the PPE comes with a declaration of conformity from the manufacturer or a certificate issued by a notified body, attesting that the product has been tested and certified according to applicable standards.

- Size and fit: The PPE must be suited to the user’s morphology to ensure effective protection and optimal comfort. Consider size options and adjustment possibilities.

- Materials and composition: Consider the materials used for the PPE, especially if the user has allergies or sensitivities to certain components.

- Instructions for use and maintenance: The PPE should come with clear instructions on its use, maintenance, cleaning, and, if applicable, replacement. This information is crucial to maintain the effectiveness of the PPE.

- Durability and expiration date: Some PPE has a limited lifespan. Check the durability of the product and the presence of an expiration or recommended replacement date.

- Storage and transport: Ensure that storage and transport conditions will not compromise the quality and effectiveness of the PPE.

- Total cost of ownership: Consider not only the purchase price but also the costs associated with maintenance, replacement, and user training.

- Reputable supplier: Purchase from reputable and reliable suppliers who can provide technical advice and after-sales support.

- Returns and warranties: Check the return policy and warranties offered for the PPE. In case of failure or non-compliance, it is important to have the option to return or exchange the product.

Example: To mitigate risks for employees in the manufacturing plant, the following PPE are purchased:

- Respiratory masks with appropriate filters: These masks are designed to filter dangerous chemical vapors, thus preventing the inhalation of harmful substances. It is crucial to choose filters suited to the specific type of solvent or chemical used, as different filters are designed for different types of contaminants.

- Safety goggles with side protection: To protect the eyes from chemical splashes. These goggles must be well-fitted and provide protection from splashes coming from all directions.

- Gloves resistant to chemicals and cuts: Gloves specially designed to withstand exposure to specific chemicals. These gloves must be selected based on the required chemical resistance, comfort, dexterity, and the ability to handle materials safely.

What’s Next?

The provision of PPE must be complemented by adequate training on its correct use. Workers must know how to put on, take off, adjust, and maintain their PPE. Additionally, a regular program of verification and maintenance is essential to ensure that the PPE remains in good condition and continues to provide the necessary level of protection.

Example: The company implements a continuous monitoring program to assess the effectiveness of control measures. This includes regular inspections, tracking of incident reports, and periodic health assessments for employees. Six months after implementing mitigation measures, a review is conducted, showing a significant reduction in machine-related incidents and improved air quality in work areas. Based on these results, adjustments are made to further improve workplace safety and health.

As a safety manager, you must keep the following key information up to date:

- A safety register containing all your equipment life records (PPE and CPE) . Each piece of equipment must be regularly checked according to the manufacturer’s requirements. It must also be discarded before it expires or if it is damaged.

- A personnel register proving that users are properly trained in the use of these equipments.

- A risk analysis document proving your analysis of hazards and the follow-up on actions to reduce them.

- An internal regulation and communications to employees informing them of hazards and reduction measures.

For this, it is sometimes preferable to use PPE management software.

.

.